The Create Fillet Surface command creates a surface between two selected surfaces, trimming the original surfaces by default.

This command is useful for sheet metal design (for example, for car bodies) to provide a smooth transition between two adjacent surfaces—perhaps for aesthetic quality or because of a manufacturing requirement.

To create a fillet surface at the intersection of two selected NURBS surfaces:

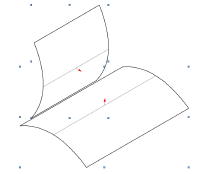

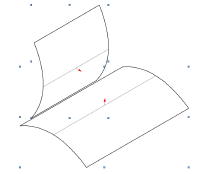

1. Select two NURBS surfaces. The position of the fillet surface depends on the normal of the NURBS surfaces; select Show Normal in the Object Info palette to display the surface normals (see Displaying Surface Normals).

2. Select Model > 3D Power Pack > Create Fillet Surface.

The Fillet Surface Preferences dialog box opens. Enter the desired Fillet Radius, and then select the trim and cross section type for the fillet.

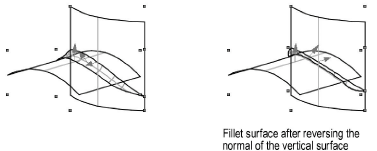

The following trim type examples use a circular cross section type, and the cross section examples use an edge tangency trim type. The original surfaces are trimmed.

Click to show/hide the parameters.

3. Click OK.

A NURBS fillet surface is created between the two objects.

The position of the fillet surface depends on the surface normals. The fillet is created differently if the Reverse Normal button is clicked for one or both of the surfaces in the Object Info palette.

~~~~~~~~~~~~~~~~~~~~~~~~~